How is loft Insulation made and manufactured?

Due to the energy crisis and surging household bills, there’s understandably a rise in demand from homeowners seeking to reduce outgoing costs. This plight has increased awareness of how insulated homes can also reduce carbon emissions and help combat climate change.

One relatively low-cost but effective option for householders is to insulate the loft.

According to the Energy Saving Trust (EST), a quarter of heat is lost through the roof in an uninsulated home. Insulating your loft is an effective way to reduce heat loss, heating bills and has a 40-year lifespan.

Dyson Energy Services has been installing insulation, including loft insulation, to householders’ homes for the past 40 years. We have long established relationships with a range of quality manufacturers and only use environmentally sustainable products when installing energy efficiency measures, such as loft insulation.

We’ve invited James Rist from Superglass, an industry leading insulation manufacturer of glass mineral wool to tell us more about how loft insulation is made.

James Rist, Business Development Manager at Superglass“Dyson Energy Services is a very dependable and a trusted key installer of Superglass products and one that always aims to do the job correctly first time. I look forward to continuing our great working relationship for many years to come.”

Q: Tell us a little about yourself and your role at Superglass?

Hi, I’m James Rist and I have worked at Superglass for almost 5 years and within the insulation industry for 10 years.

I work as a Business Development Manager for Superglass, but my experience started before then when I was an Energy Performance Advisor helping both homeowners and businesses reduce their energy bills. This then led me into work with both regional and national house builders looking at what type of insulation worked best for them to achieve the required SAP calculation required.

Part of my role now at Superglass is to support our approved insulation contractors which Dyson Energy are a key member of, to ensure they can offer their customers the best value for money and help reduce people’s energy bill and their carbon footprint along the way. Within my job I work with Dyson Energy to provide clarity on what specifications we can offer and be the link between our technical department and Dyson’s customer requirements.

Q: Tell us more about Superglass and what the product is?

Superglass has a heritage of manufacturing insulation in Scotland for over 30 years. Today, we are no longer just an insulation manufacturer; we are focused on using glass science in the development of our products and we are an industry leader in sustainable construction solutions.

Superglass insulation is a glass mineral wool, which not only offers excellent thermal and acoustic performance, but is also non-combustible and breathable, reducing the risk of condensation. It consistently performs to its stated levels, and as it’s made from up to 84% recycled glass, it has outstanding environmental credentials too.

Q: Why is improving your home’s energy efficiency so important?

At Superglass we are passionate advocates of new renewable technologies, ones which save valuable energy and ultimately preserve our planet for future generations. But we are equally passionate about ensuring these technologies operate with the effectiveness and capacity they are designed to achieve. That’s why, no matter how efficient your heat source, our products are designed to protect the whole building envelope from heat wastage, and insulation is your number 1 tool for energy efficiency. Heating buildings without effective insulation is expensive. Think of the energy being used to heat a building, as water running into a bucket. If your bucket is leaking, then water just keeps flowing out of it but plug the hole and it quickly fills up. Insulation acts as that plug to keep the heat you’re generating inside the building – where it belongs. This means lower energy bills and it also improves the effectiveness of using renewable heat technologies such as air source heat pumps. The reason we advocate better, higher performing fabric is 2-fold: 1) To reduce housing C02 emissions and 2) To help reduce soaring energy bills. Without good fabric the costs of running a heat pump could be more costly than the costs of running a gas heating system.

Q: Why is insulating your loft a good idea?

As much as a third of the heat from a typical house could be escaping through the roof. Superglass loft insulation works by preventing that heat loss. Typically, homeowners can cut their energy bill by up to 20% through effectively insulating the loft space. In fact, a well-insulated building is the most cost-effective way to reduce energy bills. So not only can Superglass Loft Insulation help lower heating bills but can also lessen wear and tear on the boiler and help reduce global warming and climate.

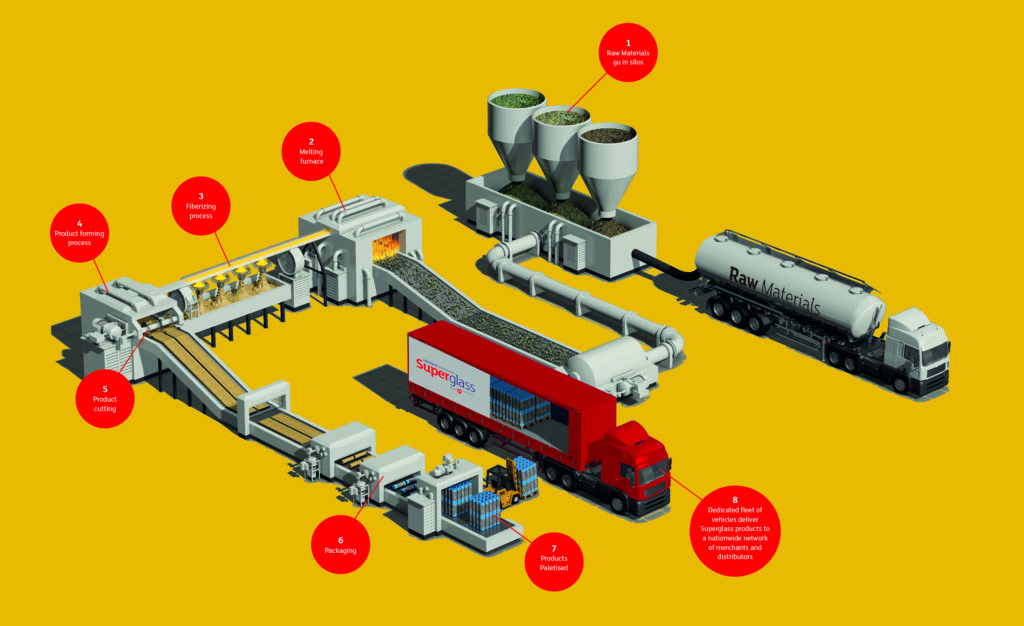

Q: Can you tell us about how loft insulation is manufactured?

The first step in creating glass mineral wool insulation is to heat recycled glass (and specific additives that help create the right glass chemistry) to a very high temperature using our new state-of-the-art furnace. When it melts, it’s then spun into thin fibres that we bind together with a resin, locking air into the gaps between the fibres. The bound fibres and resin are then cured in an oven to create resilient roll and slab products. The products are then compression packed to help reduce the carbon footprint of the transport logistics to our customers.

Europe’s most advanced manufacturing plant. As a result of one of the biggest investments in the insulation industry in recent times, our manufacturing plant in Stirling is a leading example of 21st century manufacturing.

Q: Is the loft product environmentally friendly? Is it made of recycled material?

Research has shown that over its lifetime, a typical glass wool product saves up to 300 times the energy used in its manufacture and transport. That’s what makes glass wool so exceptional from an environmental point of view. But there are even more ways Superglass insulation benefits the environment. For example, we manufacture all our glass wool insulation products from post-consumer waste, which would otherwise be diverted to landfill. Our aqueous waste and fibre waste are both recycled to prevent going to sewer or landfill; advances in our melting process mean we use less energy in production; and our products are compress-packed to around one-ninth of their original volume, reducing transport costs and the amount of packaging.

So not only does glass mineral wool save energy in use, but also in its manufacture. It reduces heating and cooling requirements so efficiently, it saves many times the energy used in sourcing the raw materials, manufacture, distribution and installation. And as it’s made from up to 84% recycled glass, it reduces waste disposal and saves valuable resources – giving Superglass products a Generic BRE Green Guide rating of A+. Furthermore, all Superglass products are manufactured in accordance with British Standard ISO 14001 – Environmental Management Systems.

When you combine all these benefits with our support of the Government’s environmental initiatives, we’re sure you’ll agree that Superglass Insulation is one of the most environmentally friendly construction materials available.

Q: Can loft insulation set on fire easily?

All Superglass products have a Euroclass A1 fire classification – the highest possible rating – so are classed as some of the safest materials on the market. Our insulation is made from waste glass, an inert, inorganic and non-combustible material. This can help protect buildings against fire by not supporting the spread of flames therefore helping to protect the building, thus limiting damage and protecting its occupants. Superglass insulation has undergone the strictest independent testing to BS EN 13501-1 Reaction to Fire standards. This follows the industry standard Euroclass system, which classifies the reaction to fire of a building material with ratings of A1, A2, B, C, D, E and F. A1 and A2 ratings mean a material does not burn or contribute to the spread of flames or emit any significant levels of toxic smoke in a fire, while materials rated B to F are combustible. As non-combustible glass mineral wool insulation, Superglass offers the extremely important benefit of effectively adding a layer of fire protection to buildings, which means that a building with Superglass insulation will have an improved fire rating.

Answers to your commonly asked questions

We asked James, from Superglass, to answer some of our consumers frequently asked questions about loft insulation.

Will rats nest in fibreglass insulation?

No, all Superglass products are non-hygroscopic, will not rot, degrade, or sustain vermin and will not encourage the growth of mould, bacteria, or fungi.

Does fibreglass loft insulation contain asbestos?

No, Superglass products don’t contain asbestos. The products are manufactured from recycled glass.

How many layers of loft insulation do you recommend?

The minimum recommended insulation thickness for retro-fit/existing lofts is 270mm. The minimum thickness for new build is determined by the required u-value for that specific loft.

How often should loft insulation be replaced?

Provided that the insulation is not damaged by liquids or mechanical damage then the insulation performance will not degrade over time. Thermal performance can be continually improved over time by adding more insulation.